End-to-end Remote Reefer Management

Two-way interface with all major reefer OEM makes and models

Real-time connectivity at every point in the supply chain

Easy and seamless interface with 3rd party systems

Real-time wireless in-cargo sensor monitoring

Easy and quick installation with the GT Sense Install App

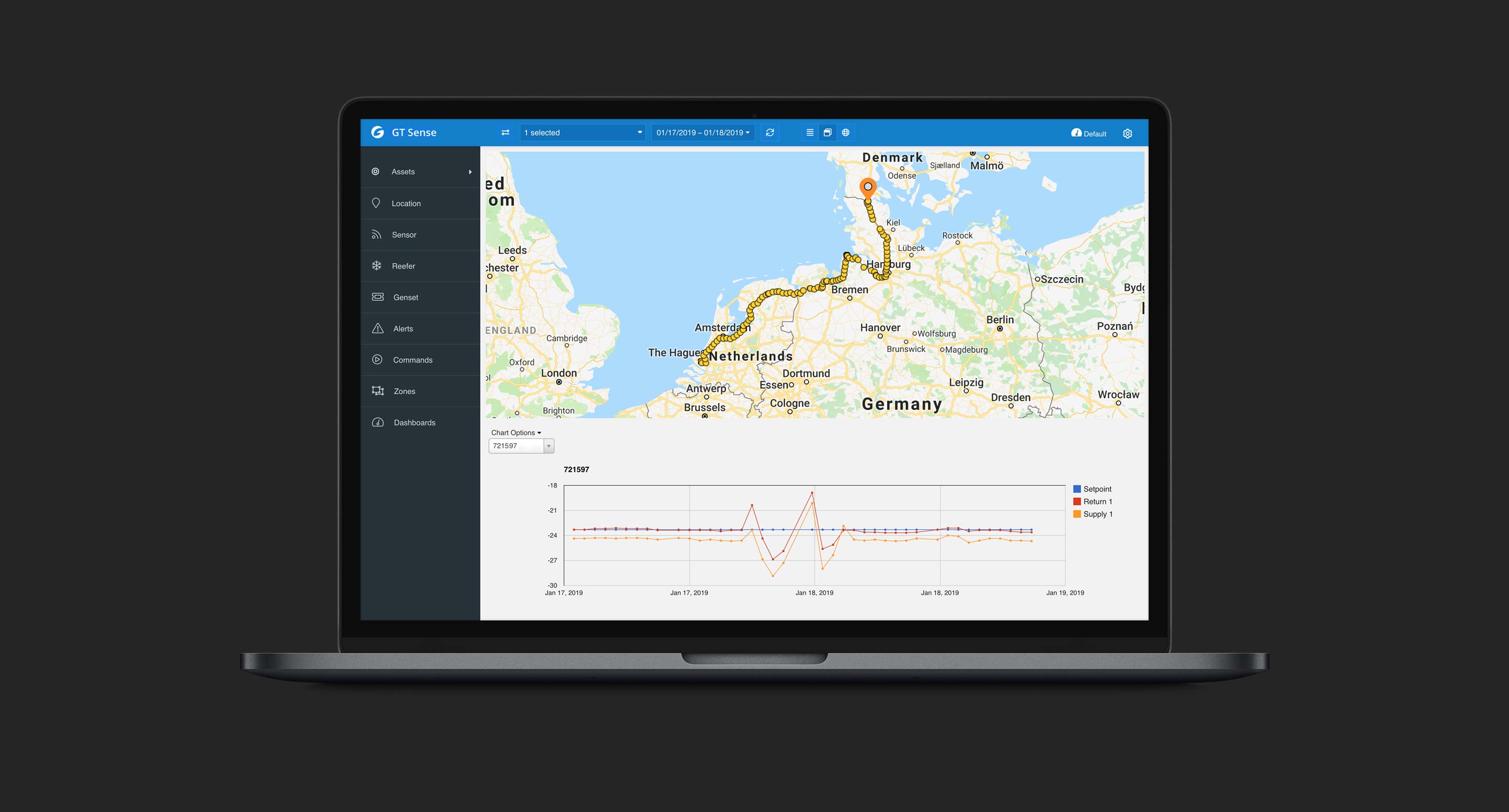

GT Sense Platform

Get real-time insight into your reefer operations at any point in the supply chain. Whether focused on cargo care or reefer operations, the GT Sense platform provides you with actionable intelligence.

Request a demo

GT Sense Device

Global cellular connectivity with a built in IoT wireless sensor gateway. When there is no cellular connectivity, data from the GT Sense device and sensor is stored and transmitted when cellular connectivity is restored.

GT Sense Vessel

The GT Sense Reefer solution can be enhanced with the IoT Vessel Network by WMS for real-time connectivity at sea.

Learn more

Tiered user access

Manage and share data selectively for more streamlined and customised operations and customer service.

Sensor Nodes

The wireless sensor nodes have a myriad of integrated sensors providing location, temperature, humidity, shock, motion, tamper, or light. The sensors nodes can communicate seamlessly with the GT Sense Reefer device and can be placed anywhere inside the reefer or in the cargo itself.

- Door

- Humidity

- Light

- Vibration

- Temperature

- Shock

- Motion

- Tamper

- Buzzer

- Jamming

Features and Benefits

The benefits of real-time remote reefer monitoring and management are vast; and vary based on your operations.

Globe Tracker assigns a Customer Success Manager (CSM) that works with customers over the long term to maximize these benefits to fit their individual needs.

Schedule a meeting to learn more about how these benefits apply to you.

- Remote monitoring and control of all major reefer types including Carrier, Thermo King, Daikin, and StarCool. Powered by RTE.

- Monitor location via GPS.

- Read and control set-point.

- Monitor temperature in real-time and report temperature excursion alerts.

- Run Remote PTI.

- 3rd party systems integration available.

Remote Monitoring and Control

- Automate and improve compliance with applicable food and pharma safety regulations.

- Mitigate load-loss or spoilage.

- Quickly identify theft, delays and deviations.

- Identify and react to cargo impact events.

- Shock and Damage Alerts.

- Remote data log file upload.

Cargo Safety and Compliance

- Calculate dwell times by geozone.

- Gate In/Out based on geozones.

- Excess detention and demurrage reports.

- Real-time reefer alarms.

- Monitor plug-in times and terminal compliance to SLAs.

- Monitor usage and run times.

- Significantly reduce or eliminate manual inspections, and reduce risks caused by human error.

- Detect operational weak spots, allocate accountability, and adjust management accordingly.

Improved Operations

- Automate and optimize reefer maintenance and service operations for more seamless operations, and maximize asset lifecycle.

- React in real-time to minimize or preempt equipment issues for more seamless operations.

- Remote software upgrades.

- Reduction in M&R costs and equipment management.

- Fast and simple installation with iOS or Android smartphone app.